The clean and convenient way to clip minnow heads, nightcrawlers, and soft plastics.

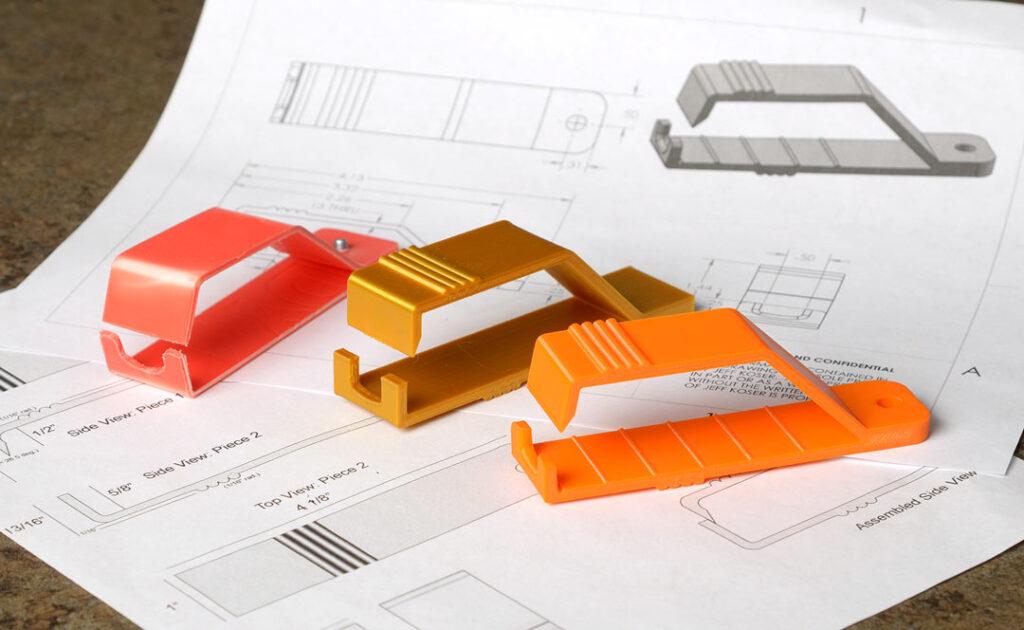

Proudly designed and manufactured by Jeff Koser in Rhinelander, WI. CAD and prototyping by Ross Abrams Engineering Student, UW Milwaukee.

$5.99

THE USES:

Minnow Heads

Half Crawlers

Ned Rigs

THE RETAIL LOCATIONS:

Minnesota

- Fred’s Bait & Tackle, Deer River

- Winnie One Stop, Deer River

Wisconsin

- Anglers All, Ashland

- Dewey Catchem And How, Minocqua

- The Fishing Hole, Rhinelander

- The Musky Shop, Minocqua

- River Rock, Ashland

- Rome Outdoors, Nekoosa

- Scottie’s Bait & Tackle, Three Lakes

- Tamarack Outfitters, Crandon

Online

THE TIPS:

THE HISTORY:

“There has got to be a better way to remove minnow heads.” is what sparked the idea of the BaitClipper while ice fishing a Minnesota lake in 2020. Scissors froze, bare thumbs and thumbnails froze, and biting them off required a pocket full of breath mints and a toothpick for after-hours socializing. Expanding the use to cutting crawlers without ruining a manicure and recycling a pile of torn wacky worms for Ned Rigging was an added bonus.

The design and manufacturing of the BaitClipper was taken up as an intentional challenge to see if a low-priced gadget could be 100 percent produced in the United States; particularly in the Midwest while allowing a reasonable profit to be made at all stages (the objective being reasonable not insanely excessive… yes that’s a bash on corporate margins). This was the perfect challenge for brainchild, Jeff Koser who has always gone against the grain and found non-traditional ways to attack budget constraints, process hurdles, and limited manpower to achieve project goals while keeping the bean counters and financial officers happy.

Having a diverse social network has been the key to meeting the challenge. Jeff’s natural curiosity, along with the gift (or curse) of gab has built a huge circle of acquaintances harboring almost unlimited expertise. Identifying mutual opportunity is also an asset. Case in point: the CAD work and prototyping was performed by UW Milwaukee Engineering Student, Ross Abrams. Ross happened to be looking for a real-world product concept that could be used to help him sharpen his CAD capabilities and fill out his portfolio. He took the concept from an amateur Photoshop rendering along with a prototype fashioned from a plastic cat litter container to a clean, useable, digital, design. Ross’s commitment to the design and functionality through 8 iterations also proved that he will be an asset to any future employer fortunate to add him to their team.

A non-traditional approach to manufacturing has also allowed initial production to move forward without a large start-up investment in produced units. While the plan is to move toward traditional injection molding for high volume, current inventory is being produced “as needed” using the same PETG plastic as planned, but utilizing 3D print farming until units sold justifies the start-up costs associated with traditional methods.

The result is a quality-produced, low-priced, essential, fishing accessory proudly manufactured in the blue-collar heart of the United States. While the margins won’t allow for anyone involved to upgrade their corporate jet, buy an executive estate, or turn the heads on Wall Street, it will give you a product that adds to the enjoyment of the sport you already love while supporting the talents and work ethic we have available in the good old USA.

God Bless!

Proudly designed and produced in the USA

THE FUTURE:

Want to get notified when the BaitClipper is available online?

Sign up for email alerts!